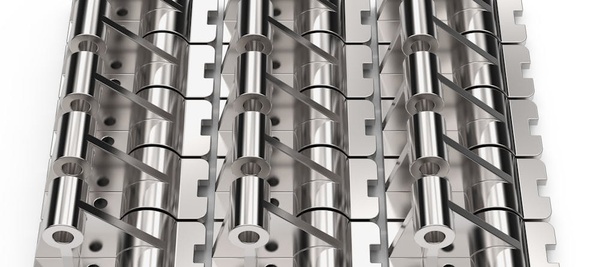

Stainless Steel CNC Machined Parts: Technical Overview and Service Considerations

The manufacture of stainless steel CNC machined parts is central to many industries requiring high durability, corrosion resistance and precision geometry. This guide addresses the material, process, cost and service-selection dimensions that organisations should evaluate when specifying stainless steel CNC parts. A provider such as Xstar with full engineering, material-sourcing and machining capabilities is representative of the class of service necessary to meet demanding specifications.

Material & Process Fundamentals

The term “stainless steel CNC machined parts” describes components fabricated from stainless steel alloys via CNC machining operations (milling, turning, drilling, EDM, etc). Such parts benefit from the alloy’s corrosion resistance, structural strength and ability to deliver complex geometries with tight tolerances. For example, one provider lists grades such as 303, 304, 316, 17-4 PH, 440C among those commonly machined.

In the context of stainless steel machining, key factors include:

-

The machinability of a given grade (for example, 303 offers enhanced machinability vs 304).

-

Tooling, feeds & speeds: stainless steel often machines more slowly compared to aluminium or low-carbon steel.

-

Post-processing and finishing: passivation, polishing, bead-blasting, surface treatment to meet final application requirements.

Can Stainless Steel Be Machined?

Yes — the question “can stainless steel be machined” is addressed by many sources confirming that with proper tooling, parameters and grade-selection, stainless steel is machinable. For instance, a machining alloy list shows grades such as 303, 304, 316, etc being routinely processed.

However, compared with softer metals, machining stainless steel imposes challenges: increased tool wear, slower cutting speeds, risk of work-hardening or heat build-up, and often higher cost per part. One design guide notes that “harder materials like stainless steel … must be machined with slower spindle RPMs and machine feed rates” which affects cycle time.

Therefore, when specifying stainless steel CNC machined parts, it is essential to evaluate whether the design is optimised for machinability (e.g., avoiding excessive deep pockets, selecting grades with better machinability) and to factor in the additional cost/time implications.

What Materials Can Be Used in a CNC Machine?

In addition to stainless steel, many other materials are compatible with CNC machining operations. The question “what materials can be used in a CNC machine” covers a broad spectrum: aluminium, steels (carbon, alloy), brass, copper, titanium, plastics and composites.

In practice, a precision machinist will select material based on application demands (strength, corrosion resistance, weight, finish) and cost. For example, stainless steel parts may be chosen for corrosion resistance (marine, chemical-processing, medical environments) while aluminium may be used for lighter weight and easier machining. Since stainless steel is harder to machine (slower feed rates, tougher tooling), part designers often assess whether alternate materials might meet the performance criteria at lower cost.

How Much Does a Metal CNC Machine Cost?

Another important question: “how much does a metal CNC machine cost” when considering manufacturing investment or outsourcing decisions. Price guides show wide ranges: entry-level machines from a few thousand dollars up to industrial multi-axis machining centres costing hundreds of thousands or more.

For example:

-

Entry-level desktop/workshop machines: US $2,000–$10,000.

-

Mid-range industrial metal CNC machines: US $30,000–$100,000+ depending on axes, automation, spindle power.

-

High-end production multi-axis centres: US $200,000–$500,000+ (or even above US $1 million) for large-scale manufacturing equipment.

These cost ranges influence part pricing, turnaround time and the ability of a machining partner (such as Xstar) to handle high precision stainless steel CNC machined parts at scale.

Can CNC Machine Cut Metal?

When exploring precision components, you may ask: “can CNC machine cut metal?” Yes — modern CNC machines (mills, lathes, multi-axis centres) are routinely used to cut, mill, turn and drill metal materials including stainless steel. They incorporate rigid structures, coolant systems, tooling designed for metal cutting, and software control for precision. For example, material-datasheets note that stainless steel machining is a classical application for CNC machining services.

Metal-cutting capability is extended by modern features: five-axis machining, high-rigidity spindles, tool changers, automatic work-holding, and even hybrid machining (CNC + EDM). These features enable the manufacture of complex stainless steel CNC machined parts with tight tolerances across industries such as aerospace, medical devices, energy and industrial automation.

Selection Criteria for Stainless Steel CNC Machined Parts Services

When procuring stainless steel CNC machined parts (for example from a provider like Xstar), procurement teams should evaluate the following service criteria:

-

Material grade expertise: Does the vendor machine relevant stainless steel grades (e.g., 303, 304, 316, 17-4 PH, 440C) and have tooling/process knowledge to avoid issues such as work-hardening?

-

Machine capability: Are multi-axis CNC mills or Swiss-turning centres available for complex geometries, and does the vendor have proven experience in high-precision, tight-tolerance stainless parts?

-

Finishing/post-processing: Are processes such as polishing, passivation, bead-blasting, electropolishing and surface treatment offered? These are often required for stainless steel parts.

-

Quality assurance: Does the supplier maintain documented procedures, inspection capabilities (CMM, 3D‐scanning), traceability of material and finish? For example one vendor lists ±0.001 mm tolerance on stainless turned parts.

-

Cost and lead-time transparency: Given the higher cost and slower machining of stainless steel compared to softer materials, clear quotation of cycle time, tooling, material, finishing and batch quantity is essential.

-

Scalability and logistics: For larger volume runs of stainless steel CNC machined parts, logistics, production capacity and repeatability become critical.

Application Examples and Industry Impact

Stainless steel CNC machined parts are widely used across sectors. Some examples:

-

316 stainless steel parts for marine or chemical environments: one supplier describes machining 316 parts for valves, flanges, medical implants.

-

Swiss-style machining of stainless parts for medical, aerospace and defence: multi-axis machining with tight tolerances and finish requirements.

-

General purpose stainless machined parts (grades 303/304) for automation equipment, food processing, off-road machinery.

The durable, corrosion-resistant nature of stainless alloys combined with precision CNC machining make these parts valuable for high-performance, high-reliability applications.

Cost Drivers for Stainless Steel CNC Machined Parts

While discussing stainless steel CNC machined parts, it is essential to understand the main cost drivers:

-

Material cost: Stainless steel is typically more expensive than aluminium or mild steel. As one guide notes, 304 stainless steel costs about 2–3× as much as a comparable aluminium alloy.

-

Machinability and cycle time: Machining stainless steel typically requires slower feeds and speeds, more rigid tooling, and therefore increased machine hours per part.

-

Finishing and post-processing: Surface treatments such as passivation, polishing, bead-blasting, plating add cost.

-

Tight tolerances and complex geometry: More complex parts require multi-axis machining, more setup, CAM programming, fixturing – all increasing cost.

-

Batch size: Larger volumes amortize tooling/setup cost; small runs cost more per part.

-

Inspection/quality assurance: If tolerances are tight and inspections robust, cost increases accordingly.

Thus when specifying stainless steel CNC machined parts, it is prudent to align design, material grade, batch quantity and finishing requirements to the budget, production schedule and functional demands.

Summary

In summary, stainless steel CNC machined parts represent a mature, technically demanding manufacturing domain. The material advantages of stainless alloys (corrosion resistance, strength, durability) together with the precision of CNC machining allow production of complex, high-performance components for demanding industries. The questions “can stainless steel be machined?”, “what materials can be used in a CNC machine?”, “how much does a metal CNC machine cost?”, and “can CNC machine cut metal?” all point to fundamental considerations in process planning, vendor selection and cost control. A capable service provider (such as Xstar) that offers full material knowledge, advanced CNC capabilities, finishing services and quality assurance is best positioned to deliver robust solutions for stainless steel CNC machined parts.

We are a manufacturing-and-trading integrated company specializing in CNC machining services, primarily focused on contract CNC production and high-precision metal component machining. As a professional provider offering stainless steel cnc machined parts products, stainless steel cnc machined parts manufacturers, and stainless steel cnc machined parts price information, we deliver customized and dependable machining solutions for a wide range of industries.

Our machining capabilities include aluminum extrusion CNC machining, stainless steel CNC machining, magnesium alloy CNC machining, acrylic CNC machining, ABS CNC machining, and plastic CNC machining. We also support advanced production for robot component machining, aerospace parts machining, marine parts machining, automotive parts machining, and medical parts machining, covering precision part manufacturing across multiple industrial applications.

Our CNC machining services provide outstanding accuracy, fast processing efficiency, reliable quality stability, and excellent compatibility with diverse project requirements. We offer a complete set of post-processing options, including sandblasting, hard anodizing, micro-arc oxidation, grinding, polishing, painting, blackening, electroplating, vacuum plating, chemical plating, phosphating, passivation, silk-screen printing, and textured finishing to meet complex surface treatment demands.

As a dedicated CNC machining service manufacturer, we supply both prototype machining and large-scale CNC production. If you need CNC machining service pricing or wish to discuss a custom machining project, feel free to contact us.

Some content in this article is sourced from the internet. If there is any inappropriate content, please contact us for removal.