Understanding Custom CNC Machining Cost and Material Choices (including Stainless Steel)

Custom Precision Machining – Excellence in Tailored Manufacturing

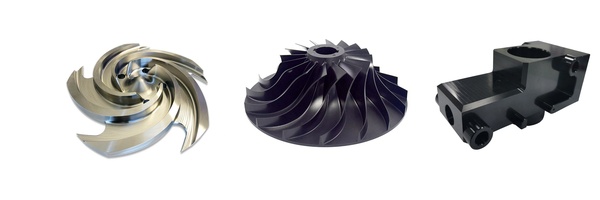

The value of custom precision machining

When your project demands both superb accuracy and bespoke geometry, custom precision machining becomes a critical enabler. At Xstar, we specialise in delivering precision-machined components tailored to your designs and performance needs. In this article we’ll explore what custom precision machining is, how the process works, what to look for in a partner, and how global and local considerations matter.

What is custom precision machining?

At its essence, custom precision machining refers to manufacturing parts to unique specifications using high-precision tools and techniques—rather than using generic or standard components. The goal is to meet very tight tolerances, exact geometries, specific materials or specialised finishes. This demands not only skilled machining but also design foresight, correct material selection, and robust quality processes.

Why choose precision custom machining manufacturers?

Selecting among precision custom machining manufacturers means you are choosing companies that specialise in high-accuracy machining rather than general fabrication. These manufacturers typically invest in 4- or 5-axis CNC machines, advanced inspection equipment (CMMs), and quality management systems (e.g., ISO, AS9000). For companies needing parts with tight tolerances, fine finishes, or complex geometry, this specialization matters. For example, one site describes a full-service CNC machining department producing “precision-machined parts that meet our customers’ most challenging specifications”.

At Xstar, our manufacturing partners act as precision custom machining manufacturers, delivering parts with high repeatability, reliable quality and on-time delivery.

The rise of custom CNC machining—global & local

In modern manufacturing, custom CNC machining has become the hallmark of precision, flexibility and speed. Whether you need a single prototype or a batch of thousands of components, CNC machining allows you to go from CAD design to finished part efficiently. Providers describe services like: “online CNC machining service … fast turnaround (3–5 days) … upload your design for an instant quote”.

The ability of custom CNC machining to scale and adapt is ideal for many industries (aerospace, medical, automotive) where custom geometry, exotic materials or rapid iteration are required.

Custom CNC machining near me

For many users, locating a supplier with good communication, proximity and support means searching for custom CNC machining near me. A local or regional supplier often provides advantages: easier communication, faster sample reviews, lower logistics overhead and potentially faster lead times. When evaluating local capability, ensure the provider meets the precision and volume requirements of your project.

Custom CNC machining China

In a globalised manufacturing environment, many firms consider custom CNC machining China to benefit from cost efficiencies, production capacity and scale. However, choosing an overseas partner introduces considerations like lead time, logistics, quality control and communication. At Xstar we partner with both domestic and China-based precision CNC suppliers to offer flexible solutions depending on budget, timeline and part complexity.

Custom CNC machining UK

Similarly, if you’re based in Europe or servicing EU clients, custom CNC machining UK gives regional advantage: familiar regulatory standards, reduced shipping times, easier visits and potentially lower import/export complexity. A savvy manufacturing strategy might combine UK precision partners for fast prototyping and offshore production for larger volumes.

Cost factors: custom CNC machining manufacturer & custom CNC machining cost

When you engage a custom CNC machining manufacturer, you must understand how cost is driven. Key cost factors in custom precision machining include: material choice, machine set-up time, number of machine axes, complexity of geometry, finishing operations, inspection and quality control. Many suppliers will provide a breakdown or fast quote so you know: what you’re paying for and why. As part of your evaluation, ask for a clear cost-quote that clarifies these elements and gives you confidence in the timeline and quality.

Materials & speciality: custom CNC machining stainless steel

Materials matter. Among the many materials used in precision machining, stainless steel is common for strength, corrosion resistance and durability. If you require parts in stainless, you would specify custom CNC machining stainless steel to emphasise the material challenge: stainless steels are harder to machine than softer metals and demand robust tooling, machine rigidity and good process control. A precision machining partner should be able to demonstrate capability for stainless, exotic alloys and assemblies with tight tolerances.

Online capabilities: custom CNC machining online

Finally, the rise of digital manufacturing means more platforms are offering custom CNC machining online: instant quoting, CAD upload, automated quoting engines, global supplier networks and streamlined logistics. For example, one service lets you upload your CAD file, select material/finish, and get a quote and timeline in minutes. At Xstar we leverage these online capabilities for faster lead time and better transparency, combining that with hands-on engineering and quality control.

The process at Xstar: how we deliver custom precision machining

Our workflow for delivering custom precision machining is structured and rigorous:

-

Consultation & Design Review – We engage with your team to understand the functional requirement, tolerance expectations, material needs, quantity, budget and timeline.

-

Supplier Matching & Setup – Based on your requirements we select among our network of precision custom machining manufacturers for best fit (domestic, UK, China) depending on cost/timeline.

-

Programming & Fixturing – For each part we ensure tool-paths, machine setup, fixturing, tooling are optimized for precision, minimal variation and efficient production.

-

Machining & Monitoring – Using the selected CNC machines, including milling, turning, 4-/5-axis operations, we execute the production. Inspection throughout ensures tolerances are met and finishes are correct.

-

Finishing, Assembly & Inspection – Any necessary secondary work (surface treatment, coatings, heat-treatment, assembly) is managed. Final inspection reports are generated and delivered with your parts.

-

Delivery & Support – Your parts are shipped with documentation, and we support any launch readiness, quality feedback or iteration you require.

Benefits of working with an experienced partner

When selecting a partner for custom precision machining, like Xstar, you gain:

-

Accuracy & quality – Because we focus on precision, you get parts that meet or exceed specification.

-

Flexibility & scalability – Whether you need a single part or a production run, we adapt.

-

Transparent cost & timeline – You understand your cost drivers, lead-time drivers and delivery expectations.

-

Global and local advantage – From “custom CNC machining near me” to “custom CNC machining China/UK”, we offer options.

-

Material and process expertise – Including tasks like stainless steel, exotic alloys, or finishing.

Summary

In short: if your project demands high-accuracy, bespoke geometry, unique materials or tight tolerances, then custom precision machining is the right strategy. By selecting expert services ranging from precision custom machining manufacturers, to leveraging custom CNC machining online, and by understanding costs with custom CNC machining cost, plus choosing the right region (near me, China, UK), you place your project on a strong foundation. At Xstar we’re ready to partner with you to turn your precision design into reality.

We are a combined manufacturing and trading company specializing in CNC machining services, primarily focusing on outsourced CNC production and the precision fabrication of a wide range of metal parts. Our machining capabilities include CNC aluminum profiles, CNC stainless steel, CNC magnesium alloy, CNC acrylic, CNC ABS, and numerous CNC plastic materials.

We also support high-accuracy machining across multiple industries, including robotics machining, aerospace parts machining, marine components machining, automotive parts machining, and medical parts machining, meeting the CNC precision requirements of most industrial applications.

Our CNC machining services deliver excellent dimensional accuracy, fast turnaround time, stable quality, and strong material compatibility. A full range of surface finishing processes is available, including sandblasting, hard anodizing, micro-arc oxidation, grinding, polishing, painting, blackening, electroplating, vacuum coating, chemical plating, phosphating, passivation, silk printing, and textured etching.

As a professional CNC machining manufacturer, we offer both small-batch and mass-production CNC services. For custom precision machining product information, custom precision machining manufacturer details, or custom precision machining pricing inquiries, you are welcome to reach out to us anytime.

Some content in this article is sourced from the internet. If there is any inappropriate content, please contact us for removal.