How to Choose the Right Copper CNC Machining Service for Your Project

Why Copper CNC Machining Is a Strategic Choice

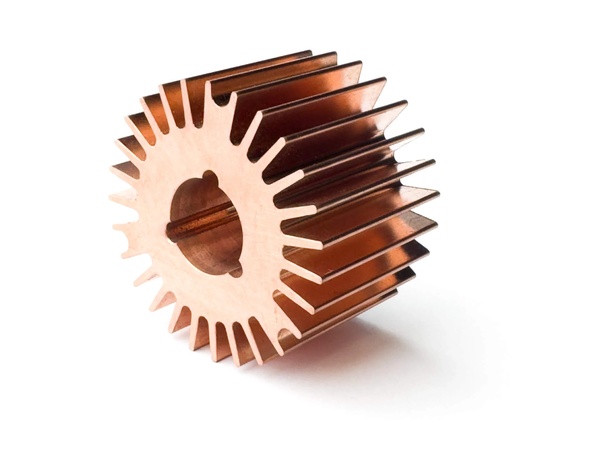

When you require precision metal parts with special properties, copper CNC machining offers a compelling solution. Copper’s excellent conductivity, corrosion resistance and machinability make it highly suited for parts in electronics, heat-sinks, connectors and more. Working with an expert like Xstar ensures you get the right material grade, tooling and process control for optimal outcomes.

Key Core Insights from Industry Sources

Based on current industry commentary and service providers, you’ll see several major themes:

-

Copper is highly conductive and corrosion resistant, which adds value especially for thermal and electrical applications.

-

Pure copper (like C101) or high-conductivity copper gives great performance but presents machining challenges (softness, tool wear, chip formation) in cnc environments.

-

Machining copper requires correct tooling, feed-rates, coolant and design considerations to avoid problems like built-up edge, smearing, or surface finish issues.

-

Service platforms offer dedicated “copper cnc machining services” (custom parts in C101/C110) with finishing options for prototypes as well as production.

-

Cost, grade selection and manufacturability matter: since copper is expensive and difficult in some respects, designers often must optimise to use copper only where its special properties are needed.

These core insights guide how companies approach copper CNC machining projects and why working with an experienced service provider (like Xstar) can make the difference.

What to Expect from a Copper CNC Machining Service

A quality copper CNC machining service will help you through material choice, tooling strategy, machining setup and finishing. Here’s a breakdown of the key considerations:

Material & Grade Selection

-

For electrical and thermal critical parts, ultra-pure copper like C101 is common; for general parts C110 or copper alloys may be used.

-

Since copper is relatively soft yet ductile, different grades influence machinability and cost.

-

Designers should evaluate whether copper is truly required, or whether a copper alloy would suffice.

Tooling, Machining Strategy & Setup

-

Because copper is soft and can form built-up edge, sharp tooling (HSS or carbide) with proper coatings is essential.

-

Feed-rate and spindle speed must account for copper’s thermal and chip behaviour. Low to moderate feed rates reduce heat buildup and surface smearing.

-

Cooling or lubricant control matters: since copper conducts heat well, managing heat in the cut zone helps maintain accuracy and tool life.

-

Fixtures and tool path planning must account for copper’s ductility and work-hardening or smearing tendencies.

Finishing & Quality Control

-

Because many copper machined parts serve in thermal or electrical applications, surface finish and precision are critical.

-

Finishing options may include electropolishing, plating (to prevent oxidation) or polishing, depending on functional requirements.

-

Cost control: since copper is expensive, the design and process must avoid over-machining or excessive material removal.

Finding Local Providers: “Copper CNC Machining Near Me”

If you search for copper CNC machining near me, you’ll want to evaluate local capabilities carefully. Here are some tips:

-

Verify the shop has experience specifically with copper — not just general CNC machining.

-

Ask about past projects: busbars, connectors, heat sinks, or custom copper components — these indicate relevant capability.

-

Ensure they can handle your finished part requirements (tight tolerances, finishing, low burrs).

-

Consider logistics, transport and lead time: even when local, specialty materials like copper may need particular handling.

-

Since copper is a higher-cost material, ask about process optimisation, quoting transparency and whether they can offer prototypes before production.

A local specialist with the right setup can save you time and cost, but for extremely specialised work you may still engage a national or specialised firm.

The Role of CNC Cutting & Milling in Copper: “Copper CNC Cutting” & “Copper CNC Milling”

When we talk about “copper CNC cutting” or “copper CNC milling” these terms refer to specific machining operations within the broader process of copper CNC machining. Understanding how they fit is helpful.

Copper CNC Cutting

While cutting often suggests simpler operations (e.g., sawing, laser), in the context of copper machining it means the removal of bulk material, roughing operations or separation of blank from stock. Effective copper CNC cutting must anticipate chip formation and tool wear because copper’s ductility and softness tend to cause built-up edge and burrs.

A well-executed cutting process preserves surface quality and reduces downstream finishing time.

Copper CNC Milling

Milling is where the detail work happens: pockets, holes, slots, surfaces. With copper, milling requires careful tool path planning and tool choice. According to machining guides for copper, milling must cope with the material’s softness and potential for smearing — for example, using wiper inserts, smaller corner radii, consistent feed.

By handling “copper CNC milling” effectively, manufacturers like Xstar can deliver parts that meet the functional as well as aesthetic requirements.

Addressing Broader Questions: “Can CNC Machine Cut Metal?”, “Can CNC Cut Metal?”, “How Much Does a Metal CNC Machine Cost?”, “What Materials Can a CNC Machine Cut?”

When integrating copper CNC machining into your manufacturing workflow, these questions often come up.

Can CNC Machine Cut Metal?

Yes — a CNC machine is designed to cut, mill, turn and drill a wide variety of metals. For copper CNC machining, the machine must be equipped with appropriate tooling, rigidity, coolant, and control to handle copper’s unique properties. Suppliers of custom services will explicitly list copper among their materials.

Can CNC Cut Metal?

In the broader sense, yes — CNC machines cut metal including steel, aluminum, titanium, copper, brass and many alloys. However, each metal has different challenges (tool wear, heat, chip formation). For copper CNC machining in particular, you need expertise around its softness and conductivity.

How Much Does a Metal CNC Machine Cost?

While this is not strictly part of the copper CNC machining service, it influences cost structure. Metal CNC machines vary widely: hobby/desktop units may cost a few thousand dollars; full industrial multi-axis CNC centres can cost hundreds of thousands. The cost influences whether a service is local or outsourced, and how much the machining time impacts part cost. Designing parts for manufacturability helps control costs.

What Materials Can a CNC Machine Cut?

Modern CNC machines can work a wide range of materials: ferrous metals (e.g., steels), non-ferrous metals (e.g., copper, aluminum, brass, titanium), plastics, composites. For each material, you must adjust tooling, feeds, speeds and finishing. When you ask about copper CNC machining, ensure the service provider is set up specifically for copper and non-ferrous metals.

Why Choose a Specialist Partner Like Xstar for Your Copper CNC Machining Projects?

Working with a provider such as Xstar gives you advantages:

-

Deep experience in copper CNC machining, with tooling and process tuned for copper alloys.

-

Full service: from design review, material grade recommendation, machining (cutting, milling, turning) to finishing and assembly.

-

Ability to handle both low-volume prototypes and higher-volume production copper machined parts while ensuring consistent quality.

-

Cost control through design for manufacturability, optimal material usage and efficient machining strategies.

-

Support for finishing requirements (plating, electropolishing) when copper’s electrical and aesthetic performance matters.

Summary

In sum, copper CNC machining is a powerful manufacturing process enabling you to exploit copper’s unique properties — high thermal/electrical conductivity and corrosion resistance — while working in a precise, automated environment. Whether you’re engaging a copper CNC machining service, searching for a provider copper CNC machining near me, or specifying operations like copper CNC cutting or copper CNC milling, you must be attentive to tooling, material grade, feeds, cooling and finishing. Understanding that CNC machines can cut metal, including copper, and knowing what materials CNC machines can cut, helps you partner wisely. While the cost of a metal CNC machine varies, your design and choice of service provider will influence your part cost. With a specialist like Xstar, you’ll be positioned to achieve high-quality copper machined parts for demanding applications.

We are a manufacturing-and-trading integrated company dedicated to providing CNC machining services, with a strong focus on contract CNC machining and custom metal parts production. Our workshop handles a broad material range, including CNC machined aluminum profiles, CNC machined stainless steel, CNC machined magnesium alloy, CNC machined acrylic, CNC machined ABS, and CNC machined plastic materials.

We also support precision machining for various sectors such as robot component machining, aerospace part machining, automotive component machining, and medical component machining, covering most CNC precision parts required in industrial applications. Our CNC machining services deliver high accuracy, fast efficiency, stable quality, and excellent compatibility with different materials and project types.

In addition, we offer comprehensive surface finishing options, including sandblasting, hard anodizing, micro-arc oxidation, grinding, polishing, painting, blackening, plating, vacuum coating, chemical plating, phosphating, passivation, silk printing, and texture etching—nearly all major post-processing techniques.

As a professional CNC machining service provider, we support both prototype and batch CNC manufacturing. For CNC machining service quotations, you can contact us anytime.

If you are searching for copper cnc machining, reliable copper cnc machining manufacturers, or competitive copper cnc machining price, you can also reach us directly through our homepage.

Some content in this article is sourced from the internet. If there is any inappropriate content, please contact us for removal.